ABOUT ESVC ENGINEERING

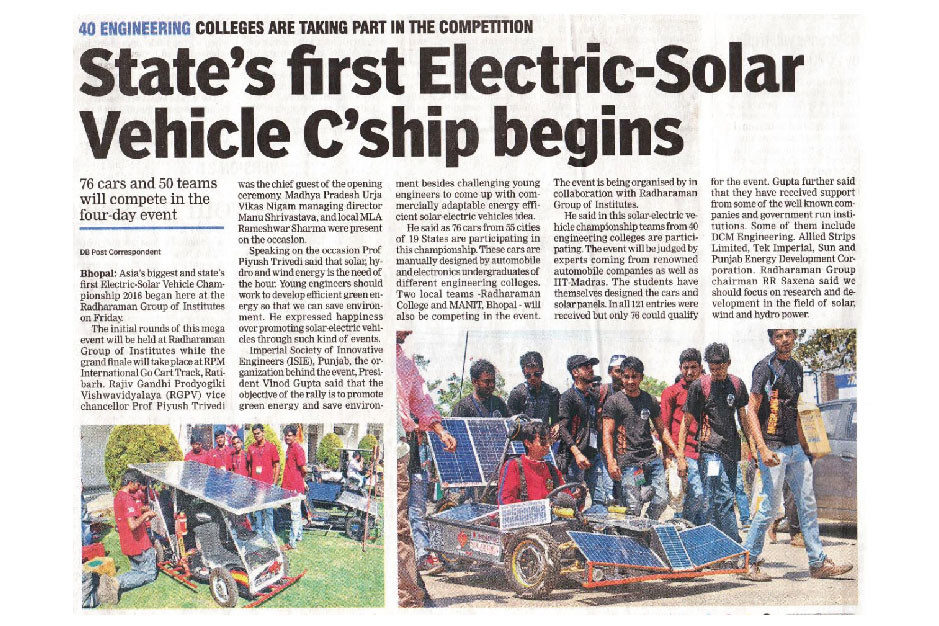

Asia’s Biggest Solar-Electric Car Design Competition

(A chain event of International Solar Car Federation)

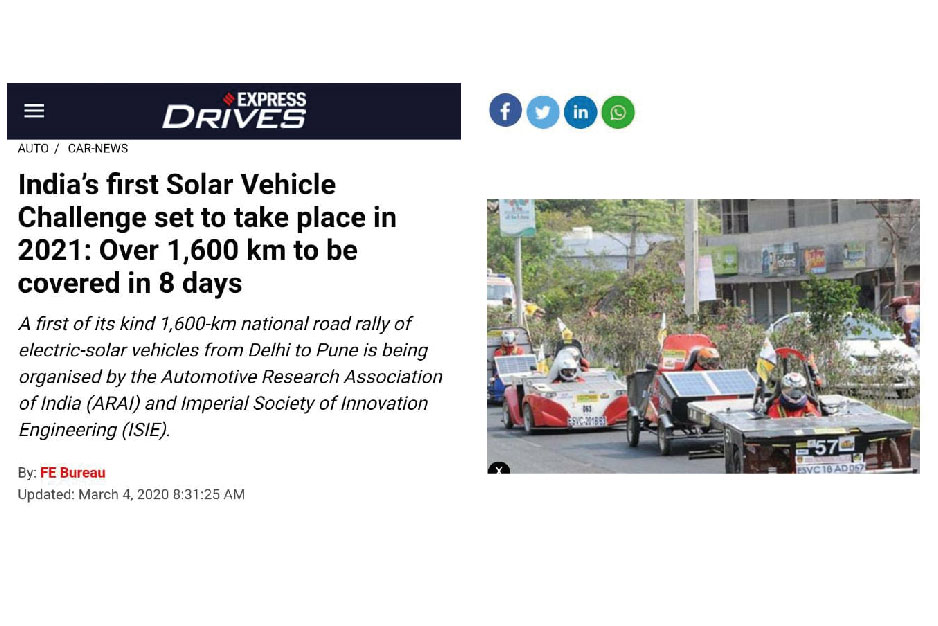

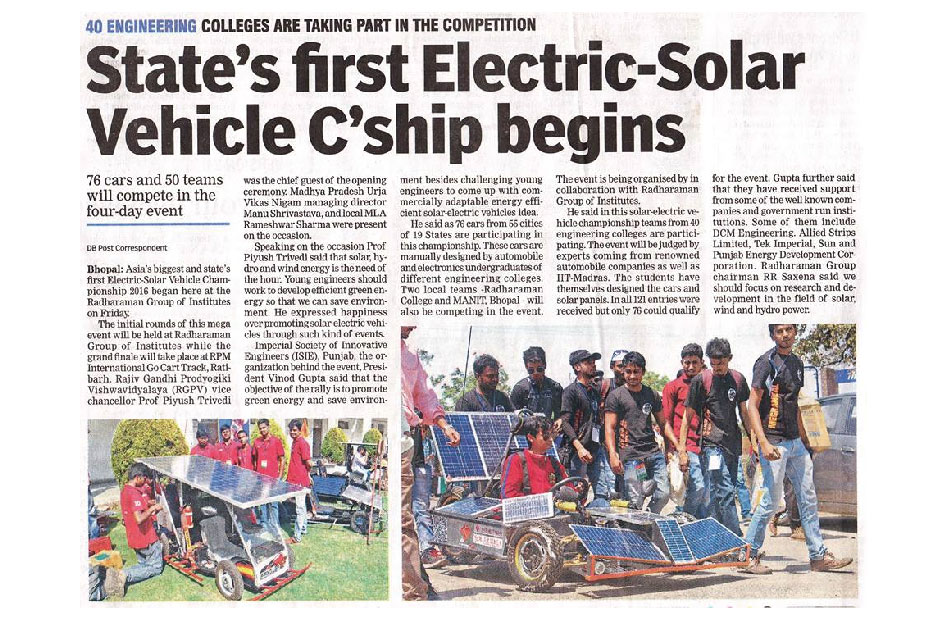

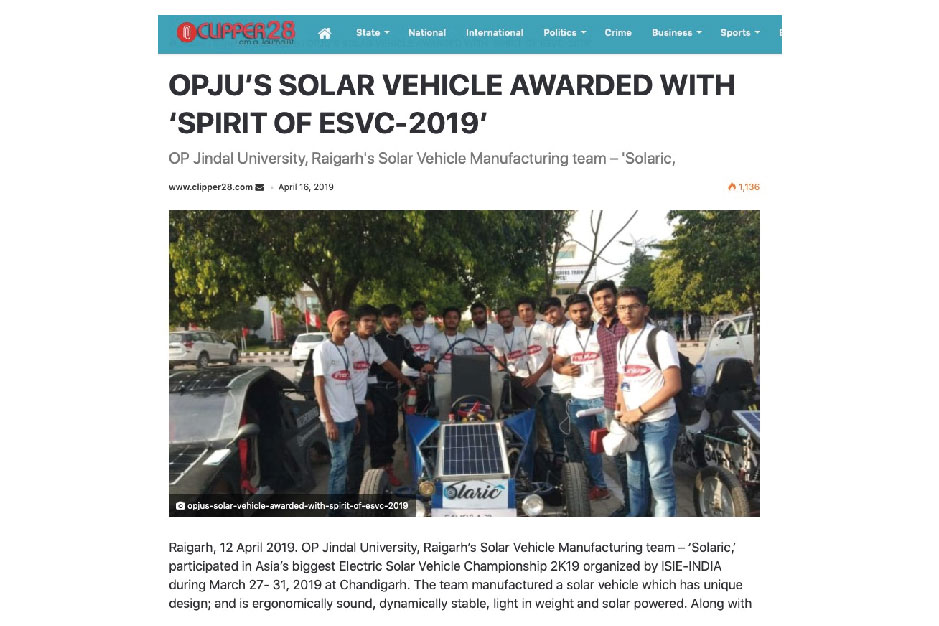

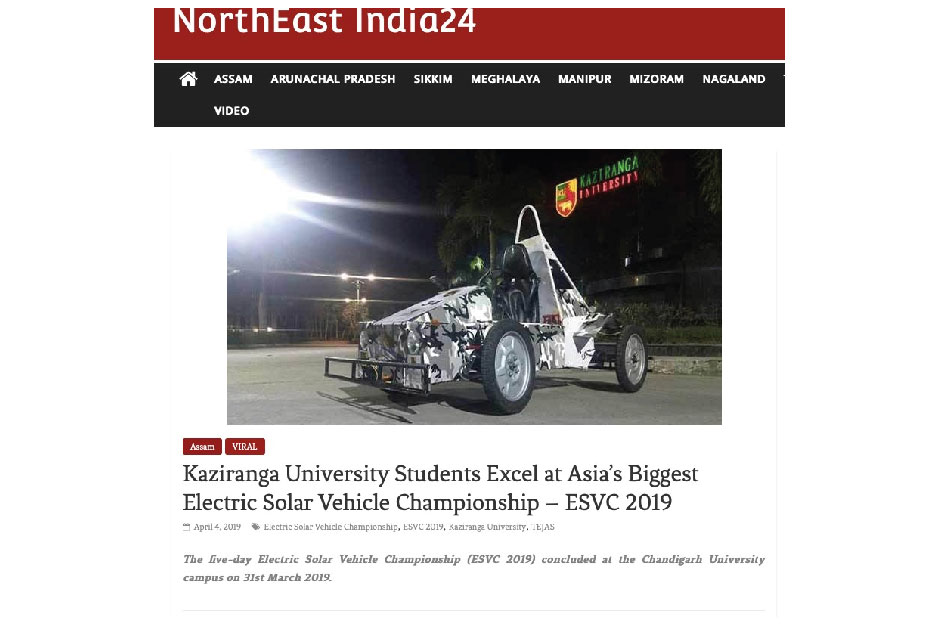

It started in 2013 (India’s 1st Electric Vehicle Event), where student teams design, manufactures and compete their solar-electric cars with other teams through various static and dynamic rounds of the event. The aim of the competition is to provide platform to students for gaining the hands-on practical experience, while applying engineering theories studied in the classroom. In addition, students learn the art of management and teamwork, which are essential skills required in the ‘real-world’. These student teams are required to build a new vehicle from scratch year-after-year and seek sponsorship and donations by their own means to fund the project. The design and fabricated prototype are being inspected and judged on teams track performance through various static and dynamic rounds.

Download Rulebook / Register for ESVC Engineering 2024

Pre Virtual Round

Mentorship Program – Teams are required to attend workshop in which the technical committee members of the event demonstrate the importance of rules, about the vehicle design and dynamics and overall vehicle concept followed by the rulebook test. The workshop also gives overview on all the event rounds evaluations, reports, Technical Inspections, enhancement of track time and college level TI, etc.

Rulebook Test – The purpose of the rulebook test is to give overall understanding of all the rules and apply best engineering skills to design the vehicle as per the rules.

Static Round

Engineering Design: The concept of the design event is to evaluate the student’s engineering process and effort that went into the design of a vehicle, meeting the intent of the competition. Prior to the event, teams are required to submit an engineering design report and a design specifications sheet for evaluation. At the competition, vehicles must be presented for design judging in finished condition, fully assembled, complete and ready-to-race. The judges will not evaluate any vehicle that is presented at the design event in what they consider being an unfinished state and will award zero points for the entire design event.

Cost and Manufacturing: The objective of the cost and manufacturing event is to evaluate the team’s understanding of the manufacturing processes and costs associated with the construction of a prototype car. This includes trade off decisions between content and cost, make or buy decisions and understanding the differences between prototype and mass production. Prior to the event, teams are required to submit a Cost Report with a detailed Bill of Materials and supporting documentation. At the competition, vehicles must be presented for cost and manufacturing judging in finished condition, fully assembled, complete, ready-to-travel on road. The judges will not evaluate any vehicle that is presented at the cost and manufacturing event, in what they consider being an unfinished state and will award zero points for the entire event.

Business Plan: The objective of the BPP is to evaluate the team’s ability to develop and deliver a comprehensive business model which demonstrates their product – a prototype race car – could become a rewarding business opportunity. The judges should be treated as if they were potential investors or partners for the presented business model. The business plan must relate to the specific prototype race car entered in the competition. The quality of the actual prototype will not be considered as part of the BPP judging. To convince the potential investors or partners that the team’s presentation is worthy of their time, it is required that an executive summary is submitted before the competition. The executive summary should contain a brief description of the team’s business plan.

Qualification Round

Technical Inspection: Technical Inspection Standard & Driver Safety – Each vehicle would be inspected for compliance according to rules and regulation mentioned in ESVC 2024 rulebook. Vehicle must be presented for technical inspection in finished condition i.e. ready-to-run condition. Technical inspection will not be done if the vehicle is brought in an unfinished condition.

Weight Test: The weight of the vehicle is checked to ensure it is designed and manufactured as per the weight criteria given in the rulebook.

Rain Test: Rain test is conducted to ensure the electrical safety of the vehicle. During the rain test, the tractive system must be active, and the drive wheels must be a minimum of 10cm off the ground or removed from the vehicle. It is not allowed to have a driver seated in the car during the rain test.

Brake Test: The brake test is one of the mandatory Scrutinizing/Inspection requirements which must be passed before the car will be allowed on track. During the brake test, All wheels should lock simultaneously and Car should not yaw more than 30 degrees in braking distance of 7 and track of 100 m.

Dynamic Rounds – Qualification

Acceleration Test: The acceleration event evaluates the vehicle’s acceleration in a straight line on a flat track patch. The cars need to accelerate from a standing start over a distance of 50 m on a flat surface. This distance of 50 m must be covered within 10 second of the vehicle starting from the starting line. If a vehicle fails to cover this distance then the team will receive 0 points in the acceleration round and will be disqualified.

Hill Climb Test: This round is to judge the vehicle’s gradient climbing ability. The round involves vehicle climbing at slope steadily. Teams are required to complete track in 10 seconds.

Cross Pad Test: This round intent to checks the maneuverability of vehicle, measure the Vehicle’s cornering ability along with its suspension dynamics on a flat surface. Team vehicle will start from starting line and it should travel along the track overcoming all the obstacles in-between the track. Team is required to complete track in 30 seconds.

Solar Performance Test: This is to check the solar performance of used solar panels on the vehicle in static and dynamic conditions. Teams have to keep their batteries potential at nominal operating voltage. Then teams will be given a time period of 2 hour to charge their batteries using solar panels. Then teams will have to run their vehicle for 45 minutes. Both static and dynamic performance of the vehicle will be checked during the round.

Durability Test: Durability Test is designed to evaluate the overall performance of the car and to test the car’s durability and reliability of the car. The vehicle has to endure for 45 minutes continuously; the cars with prolong 45 minutes run without mechanical/electrical breakdown will be qualified for the rally.